Chi tiết sản phẩm

Các nhà máy luyện điện cảm là các thiết bị sử dụng dòng điện tần số trung bình để làm nóng và làm tan chảy kim loại và các vật liệu nhiệt độ cao khác. Chúng được sử dụng rộng rãi trong các ngành công nghiệp khác nhau, chẳng hạn như luyện kim, Khai thác, trang sức, và hàng không vũ trụ, để sản xuất hợp kim, đúc, Ingots, và các sản phẩm khác. Các nhà máy luyện tập cảm ứng có nhiều lợi thế so với các lò nung truyền thống, chẳng hạn như hiệu quả cao, Kiểm soát nhiệt độ chính xác, Ô nhiễm thấp, và hoạt động dễ dàng.

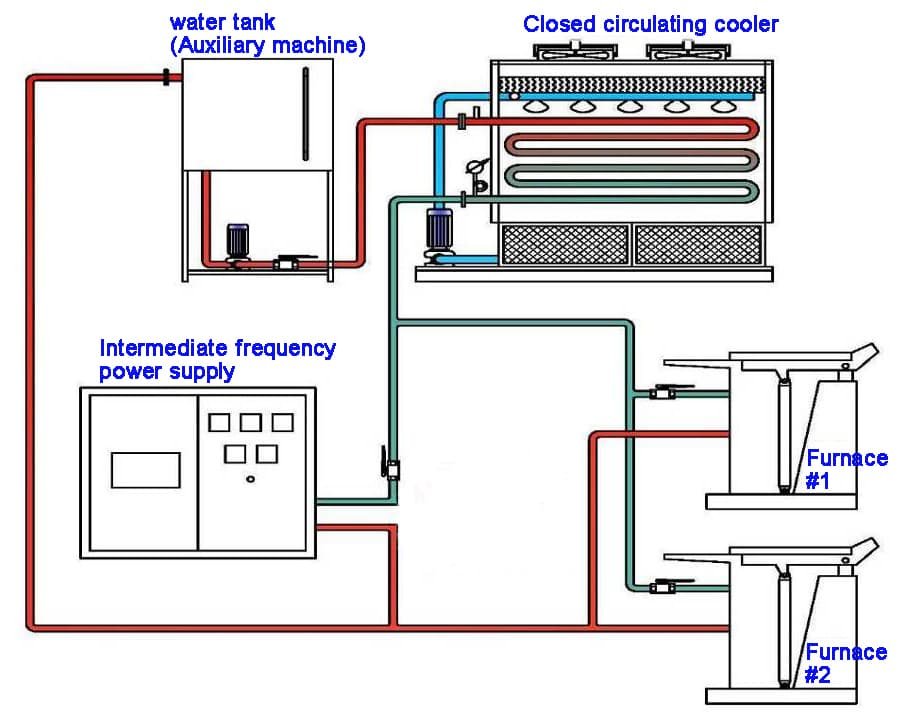

Các nhà máy luyện tập cảm ứng hoạt động bằng cách tạo một từ trường xung quanh một cuộn có chứa vật liệu được tan chảy. Từ trường tạo ra dòng điện xoáy trong vật liệu, tạo ra nhiệt và làm cho vật liệu tan chảy. Nhiệt độ và công suất của nhà máy tạo cảm ứng có thể được điều chỉnh bằng cách thay đổi tần số và điện áp của dòng điện. Quá trình nóng chảy có thể được thực hiện trong không khí, chân không, hoặc khí trơ, Tùy thuộc vào tài liệu và chất lượng mong muốn.

Các nhà máy luyện tập cảm ứng có thể làm tan chảy nhiều loại kim loại và vật liệu nhiệt độ cao, chẳng hạn như thép, đồng, nhôm, vàng, bạc, Bạch kim, Titan, zirconium, và silicon. Một số tài liệu này có tài sản đặc biệt, chẳng hạn như sức mạnh cao, chống ăn mòn, hoặc hành vi từ tính, điều đó làm cho chúng phù hợp cho các ứng dụng cụ thể. Ví dụ, Bạch kim được sử dụng để làm đồ trang sức và bộ chuyển đổi xúc tác, Titan được sử dụng để chế tạo máy bay và cấy ghép y tế, và silicon được sử dụng để làm pin mặt trời và chất bán dẫn.

Thông số sản phẩm

| Công suất định mức | 0.05T – 30T |

| Dải công suất định mức | 30KW – 12000KW |

| Dải tần số | 250Hz – 2500Hz |

| Phạm vi điện áp nội tuyến | 380V. – 1500V. |