Energy efficiency

- Direct heating process: The induction furnace directly generates heat inside the heating object through electromagnetic induction, without the need to transfer heat energy through traditional combustion or heating of external media. This direct heating method avoids heat loss during energy transmission and improves energy utilization.

- Rapid heating and high efficiency: Induction furnaces can quickly generate high temperatures and achieve rapid heating. Compared with traditional heating methods, induction furnaces can usually convert electrical energy into heat energy more quickly and efficiently, reducing energy waste.

- Precise temperature control: The induction furnace has good temperature control capabilities and can accurately control the temperature distribution and changes during the heating process to avoid excessive consumption of energy.

- No need for preheating and heat preservation: Because the induction furnace can heat objects quickly, there is usually no need for a long preheating or heat preservation process, saving the additional energy required for preheating.

- High-efficiency conversion: The electromagnetic field inside the induction furnace can directly convert electrical energy into heat energy, and the conversion efficiency is high. Most of the input electrical energy can be converted into effective heat, reducing the waste of energy.

The energy utilization rate of the induction furnace is relatively high, because it directly generates heat inside the heating object, reducing energy loss in thermal energy transmission, and can quickly and accurately control the heating process to avoid excessive consumption of energy. This makes induction furnaces an energy-efficient heating device in many industrial sectors and helps reduce energy consumption and environmental impact.

Waste and emissions reduction

- Reduce exhaust gas emissions: Induction furnaces usually do not need to burn fuel during the heating process, so they do not produce combustion exhaust gases, such as carbon dioxide, carbon monoxide and other harmful gas emissions produced by coal-fired furnaces or gas furnaces. This helps reduce emissions of atmospheric pollutants.

- Reduce wastewater emissions: The heating process of induction furnaces usually does not involve the use of water, so compared to traditional heating methods that require water cooling or other liquid media, induction furnaces do not produce wastewater emissions.

- Reduce the generation of solid waste: During the heating process of the induction furnace, solid waste such as ash and coal-fired furnace ash is usually not produced. Traditional coal or gas furnace heating tends to produce large amounts of ash and solid waste, which does not occur with induction furnaces.

- Waste reuse: Induction furnace heating processes tend to produce less scrap or scrap, and these scraps are usually metal or other recyclable materials. This helps reduce the cost of waste disposal and promotes the reuse of waste materials.

Although induction melting furnace offer certain advantages in terms of waste and emission reduction, there are still some aspects to be aware of. For example, the cooling water used in the induction furnace production process may remove a certain amount of heat, which in some cases may require appropriate treatment of the cooling water discharge. In addition, the source of electrical energy required for induction furnaces may have environmental impacts in the electrical energy production process if it is not a clean energy source.

Compared with traditional combustion heating methods, induction furnaces are generally more environmentally friendly in terms of waste and emission reduction, especially in reducing atmospheric pollutant emissions and solid waste generation.

Carbon Footprint and Environmental Impact Assessment

- Electric energy source: The main energy source of the induction melting furnace is electric energy. Induction furnaces typically have a lower carbon footprint if they use electricity from clean sources such as solar, wind or hydropower, because clean energy produces fewer greenhouse gas emissions. However, if the electricity comes from fossil fuels, such as coal or natural gas, then the emissions produced during the production of the electricity will increase the overall carbon footprint of the induction furnace.

- Life cycle assessment: Carbon footprint assessment also includes analysis of the entire induction furnace life cycle, including manufacturing, transportation, use and scrap disposal. This helps to fully assess the environmental impact of induction furnaces.

- Energy utilization efficiency: Compared with traditional heating methods, induction melting furnaces usually have higher energy utilization efficiency and can convert more electrical energy into heat energy, thus reducing energy waste and greenhouse gas emissions.

- Reduction of waste and emissions: Induction furnaces generally reduce the generation of waste and emissions, such as reducing exhaust gas emissions and the generation of solid waste, thereby reducing the environmental burden.

- Comparison of alternative traditional processes: Carbon footprint assessment can compare induction furnaces with traditional heating methods and evaluate their differences in greenhouse gas emissions under the same production tasks.

Assessing the carbon footprint and environmental impact of an induction furnace can help determine its advantages in terms of sustainable production and environmental friendliness, as well as help develop improvement strategies to reduce emissions and increase energy efficiency. When choosing an induction furnace as a heating device, awareness of its carbon footprint and environmental impact will help develop more environmentally friendly and sustainable production options.

Environmentally friendly technologies and improvements

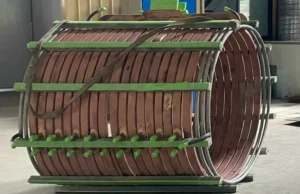

- Energy efficiency improvement: Continuously improving the energy efficiency of induction furnaces is an important improvement direction. Using advanced electronic control systems, optimizing coil design and electromagnetic field distribution, and improving heating processes can further improve energy utilization efficiency and reduce energy consumption.

- Clean energy application: Promoting the use of clean energy for induction furnaces, such as solar energy, wind energy or water energy, is an important measure to reduce its environmental impact. Switching to renewable energy sources can significantly reduce the carbon emissions of induction furnaces, thereby reducing negative environmental impact.

- Waste treatment and recycling: Research and develop more effective waste treatment technology to process and recycle waste materials or waste products generated by induction furnaces to reduce waste emissions and improve resource utilization efficiency.

- Reduce electromagnetic radiation: Induction furnaces will produce a certain degree of electromagnetic radiation during operation. Although the impact on human health is usually small, there is still room for improvement to reduce radiation levels, such as improved design and use of shielding materials.

- Life cycle assessment and environmental standards: Assess the entire life cycle of the induction furnace and formulate environmental standards and guidelines to ensure that environmental impacts are minimized during its production, use and scrapping, while promoting its sustainable development.

- Continuous innovation and research and development: Continue to carry out technological research and development and innovation, and develop more efficient and environmentally friendly induction melting furnace technology, including improvements in optimizing design, increasing efficiency, reducing waste emissions, etc.

These environmentally friendly technologies and improvement strategies can enable induction furnaces to reduce the impact on the environment during the production process, improve energy efficiency, reduce carbon emissions, and achieve a more sustainable production method. At the same time, formulating corresponding policies and standards is also the key to promoting the environmentally friendly development of induction furnace technology.

Resource utilization and circular economy

- Raw material utilization efficiency: Induction furnaces are usually used in metal smelting, heating and processing processes, and can effectively utilize conductive materials such as metals. Its high-temperature and efficient heating method helps improve the utilization efficiency of raw materials and reduces the waste of raw materials.

- Scrap recycling and reuse: The scrap generated by induction furnaces is usually metal or other recyclable materials. With appropriate processing and recycling technologies, these waste materials can be reused in production, promoting resource reuse and recycling and reducing the need for new raw materials.

- Circular economy model: The use of induction furnaces helps promote the development of circular economy models. By effectively recycling waste materials, reducing resource waste, and putting waste materials back into the production cycle, a more sustainable circular economic system can be formed.

- Waste treatment optimization: Optimize the treatment of waste generated by induction furnaces, including the reasonable treatment and resource utilization of waste residue, waste materials, waste water, etc. For example, waste residues may be reprocessed for use in the manufacture of other products, and wastewater may be purified and reused through appropriate treatment.

- Resource conservation and sustainability: The application of induction furnace technology helps achieve resource conservation and sustainable utilization. By efficiently using raw materials, recycling waste and reducing energy consumption, overexploitation of natural resources can be reduced and sustainable development promoted.

Under the guidance of the concept of circular economy, induction furnace technology is expected to promote the sustainable development of industrial production. By improving resource utilization efficiency, optimizing waste treatment, and promoting waste reuse, we can reduce dependence on limited resources, achieve resource recycling, reduce environmental burdens, and promote sustainable economic growth.

Ecological footprint and sustainable development

- Ecological Footprint: The ecological footprint takes into account the impact of human activities on the environment, including the resources consumed, the waste generated, and the pressure on the ecosystem. For induction melting furnace technology, assessing the ecological footprint means considering the resources consumed, the waste and emissions generated during production, use and end-of-life, as well as the extent of its impact on the environment and ecosystems.

- Sustainable development: As an energy-saving and efficient heating equipment, induction furnace helps industrial production develop in a more sustainable direction. By reducing energy consumption, reducing emissions, optimizing resource utilization and other measures, induction furnace technology helps promote the sustainable development of industrial production. This means meeting current needs while minimizing damage to the environment and resources, leaving a more sustainable ecosystem for future generations.

In terms of promoting sustainable development, the application of induction furnace technology helps reduce the ecological footprint of industrial production, thereby achieving a more environmentally friendly and sustainable production method. Through technological improvement, energy optimization, waste treatment and resource recycling, induction furnace technology can play a positive role in the industrial field and promote the realization of the concept of sustainable development.