Индукционные печи, как необходимое оборудование для тепловой обработки в современной промышленности, are evolving in close alignment with advancements in industrial technology and the demands of sustainable development. Looking ahead, induction furnaces are accelerating towards a future characterized by efficiency, intelligence, and environmental friendliness.

High Efficiency and Energy Savings

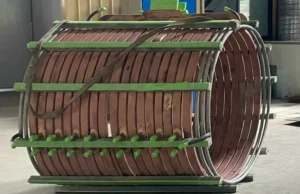

- New Induction Coil Technology:

- Optimize coil design, such as using multi-layer and shaped coils, to improve electrical energy utilization and reduce energy loss.

- Use new conductive materials to reduce resistance and heat generation.

- High-Efficiency Frequency Conversion Technology:

- Employ new power devices such as IGBT and SiC to improve inverter efficiency.

- Optimize frequency conversion control algorithms to improve power supply power factor.

- Heat Energy Recovery and Utilization:

- Utilize furnace body waste heat and flue gas waste heat for preheating to improve thermal efficiency.

- Employ heat storage technology to achieve energy recycling.

Intelligent Control

- Automated Control Systems:

- Integrate PLC, sensors, and actuators to achieve automated operation of induction furnaces.

- Implement functions such as automatic feeding, automatic melting, and automatic temperature control.

- Remote Monitoring and Diagnostics:

- Utilize IoT technology to achieve remote monitoring of индукционная печь operating status.

- Implement functions such as fault early warning, remote diagnosis, and remote maintenance.

- Expert Systems:

- Build expert systems based on big data and artificial intelligence.

- Achieve automatic optimization of process parameters and intelligent fault diagnosis.

Green Environmental Protection

- Clean Energy Application:

- Promote the use of clean energy sources such as electricity and natural gas.

- Reduce the use of fossil fuels and reduce carbon emissions.

- High-Efficiency Dust Removal and Noise Reduction:

- Employ high-efficiency dust removal equipment to reduce dust emissions.

- Employ measures such as sound insulation and vibration reduction to reduce noise pollution.

- Resource Recycling:

- Improve the recycling rate of slag and waste materials.

- Achieve resource recycling and reduce environmental pollution.

Large-Scale and Integration

- Large Induction Furnaces:

- As industrial scale expands, the demand for large induction furnaces increases.

- Large induction furnace technology is highly complex and requires breakthroughs in technical bottlenecks.

- Integrated Induction Furnaces:

- Integrate induction furnaces with other equipment to achieve production line automation.

- Improve production efficiency and reduce production costs.

Краткое содержание

The development trends of induction furnaces are multifaceted, with high efficiency and energy savings, intelligent control, green environmental protection, and large-scale and integration being the main directions. With continuous technological progress, induction furnaces will play an increasingly important role in future industrial production.