Обогрев

Предварительный нагрев: Некоторые материалы требуют постепенного нагрева, чтобы минимизировать термический шок.. This initial heating is often done slowly to a specific temperature range.

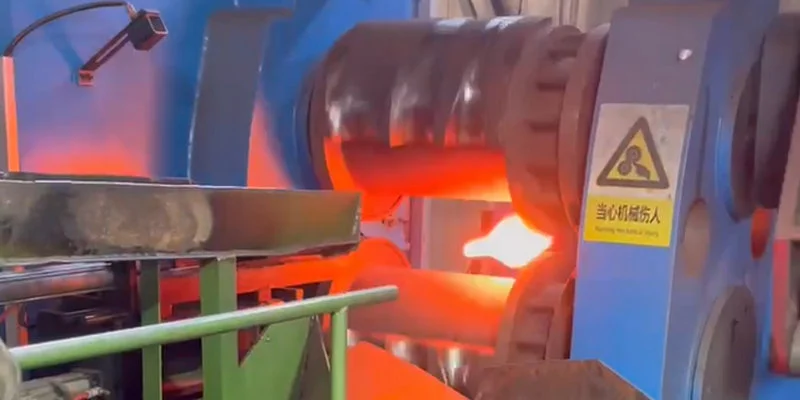

Heating to Austenitizing Temperature: This is the temperature at which the material’s microstructure changes significantly. For steel, this temperature varies based on its composition and intended properties.

Впитывание

Austenitizing: Holding the material at the austenitizing temperature for a specific period allows for the transformation of the microstructure. The duration depends on the material’s thickness and composition.

Охлаждение

закалка: After soaking, the material is rapidly cooled. There are various quenching mediums such as oil, вода, или воздух. Quenching rates affect the final properties; faster rates generally result in increased hardness.

Post-Quenching Treatment (if needed)

Закалка: После закалки, the material may be too brittle. Tempering involves reheating it to a lower temperature, allowing some toughness to return without sacrificing too much hardness.

Additional Processes (as necessary)

Отжиг: This involves heating the material to a specific temperature and allowing it to cool slowly, relieving internal stresses and improving machinability or ductility.

Нормализация: Similar to annealing, but the material is cooled in still air instead of a controlled environment, aiming for a more uniform grain structure.

Время выпуска: январь 5, 2024