Importance of Scrap Metal Recycling:

- Environmental advantages:

- Reduced energy consumption: The initial extraction of metals often requires large amounts of energy, and scrap metal recycling significantly reduces this need, helping to reduce dependence on non-renewable energy sources.

- Reduce greenhouse gas emissions: Metal production is an energy-intensive process, and recycling scrap metal can significantly reduce greenhouse gas emissions and help combat climate change.

- Reduce mineral resource mining: Scrap metal recycling reduces the demand for limited mineral resources and avoids the ecological damage and land use pressure that may be caused by the ore mining process.

- Avoid contamination: The extraction and processing of metals can produce pollutants, but the recycling process is generally more environmentally friendly and helps reduce pollution of soil, water and atmosphere.

- Resource saving advantages:

- Extend resource life: Scrap metal recycling extends the service life of metal resources and slows down the depletion of original resources by reusing metals.

- Reduced production costs: Manufacturers can reduce production costs through scrap metal recycling, as recycling metals is often more economical than extracting them from ore.

- Create a circular economy: Scrap metal recycling promotes metal materials to enter the recycling system, allowing resources to be recycled more effectively in the economy.

- Contribution to sustainable development:

- Support the green economy: Scrap metal recycling is part of the green economy, promoting the development of the industry in a sustainable direction and enhancing the image of corporate social responsibility.

- Promote social participation: The scrap metal recycling industry has created a large number of employment opportunities, including scrap recyclers, processors, etc., promoting social participation and economic development.

- Aligned with the Sustainable Development Goals: Scrap metal recycling practices are consistent with the United Nations Sustainable Development Goals (SDGs) on sustainable consumption and production.

What are the sources of steel scrap from steel mills?

- Scrap steel recycling: This includes scrap steel from scrap projects such as building structures, bridges, vehicles, machinery and equipment. The steel is typically dismantled and separated before being sent to steel mills for recycling and reuse.

- Abandoned machinery and equipment: Mechanical equipment, tools, vehicles, etc. that are no longer used or scrapped. The metal parts contained therein are usually classified as scrap steel and sent to steel plants for recycling after appropriate treatment.

- Construction and demolition waste: Waste steel generated during construction and demolition, such as abandoned building structures, reinforced concrete waste, etc., are sources of steel scrap from steel plants.

- Industrial production waste: Some scrap steel generated in the industrial manufacturing process, such as residual materials and waste materials from cutting, stamping, welding and other processes, can be recycled and sent to steel plants for reuse.

- Automobile scrap: Scrap steel generated from car dismantling and scrapping, including metal parts of scrap cars, such as body parts, engine parts, etc., is usually also a source of scrap steel from steel mills.

- Wasted electrical and electronic equipment: E-waste contains a certain amount of metal, including waste electrical equipment, cables, wires, etc., which can become part of the scrap steel in steel mills.

- Metallurgical waste: Waste generated during the metallurgical process, such as metallurgical slag, abandoned metallurgical equipment, etc., is also part of the raw materials obtained by steel plants.

- Abandoned building structures and infrastructure: The end or replacement of certain large-scale projects may result in some abandoned building structures or infrastructure, and the scrap steel in them is also part of the scrap source of steel plants.

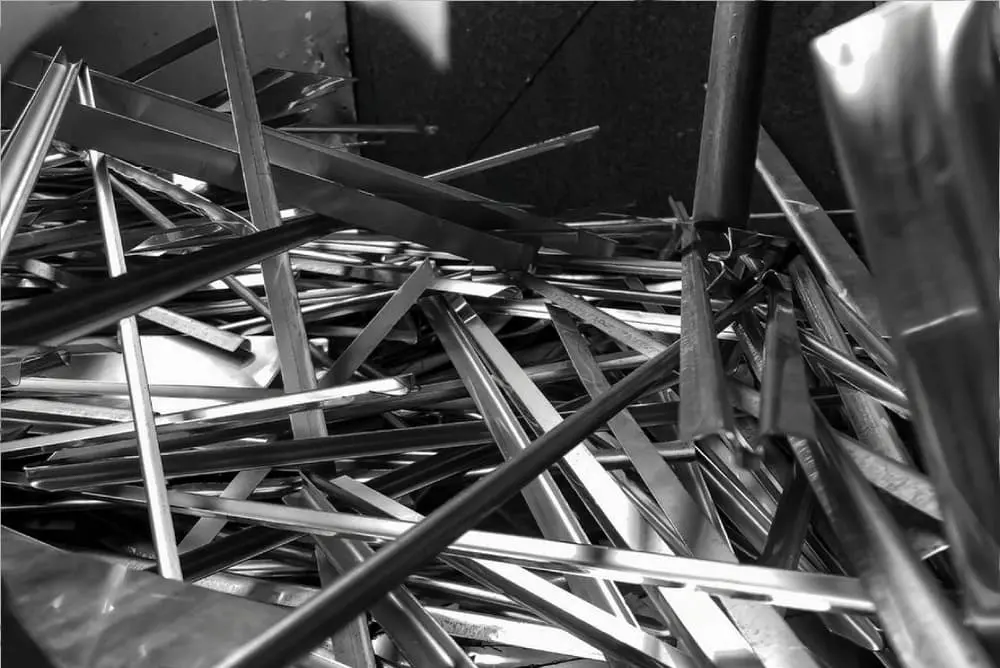

Scrap steel pretreatment:

- Collection and classification: Collect scrap steel from various sources, such as demolition sites, abandoned buildings, scrap machinery and equipment, etc. Sort the collected scrap steel into piles according to different types, sizes and qualities.

- Cleaning and removal of impurities: Clean the dirt, attachments and debris on the surface of scrap steel. This includes the use of mechanical equipment, water washing or air cleaning to ensure that the scrap surface is relatively clean.

- Cutting and Separation: For larger scrap steel components, cutting and separation may be required for better handling and transportation. Cutting can be performed using techniques such as flame cutting, plasma cutting or mechanical cutting.

- Magnetic separation: Scrap steel usually contains a certain amount of iron, and magnetic separation equipment, such as a magnetic separator, can be used to separate the iron part from non-magnetic impurities.

- Removal of harmful substances: Process harmful substances that may be present in scrap steel, such as coatings, paints, adhesives, etc. This can be achieved by chemical treatment, thermal treatment or mechanical removal.

- Crushing and crushing: For large pieces of scrap steel, it may be necessary to crush or crush it to better adapt to subsequent processing processes. This can be done by equipment such as hammer crushers, jaw crushers, etc.

- Wet cleaning: Wet cleaning can be used to remove the oil and dirt that may be attached to the scrap steel, using water or other cleaning liquids.

- Screening and grading: Screening and grading are carried out according to the particle size of scrap steel to ensure that uniform raw materials can be obtained in the subsequent smelting process.

- Quality testing: Carry out quality testing of scrap steel, including testing of chemical composition, physical properties, etc., to ensure compliance with steelmaking requirements.

The role of induction furnaces in scrap metal recycling

- Efficient heating tools:

- Principle of electromagnetic induction: Induction electric furnaces use the principle of electromagnetic induction to convert electrical energy into heat energy, which can heat metal materials quickly and efficiently.

- Quickly reach high temperatures: Induction electric furnaces can quickly heat scrap metal to high temperatures, which is suitable for melting and processing various metals and improves production efficiency.

- Multi-metal processing capabilities:

- Suitable for a variety of metals: Induction furnaces can process a variety of metals including iron, copper, aluminum, etc., making it a versatile scrap metal processing equipment.

- Alloy processing: For alloys or mixed metals in scrap metal, induction furnaces can also effectively separate and process them.

- Flexibility and precise control:

- Precise temperature control: Induction electric furnaces have precise temperature control that can be adjusted according to the melting points and processing needs of different metals.

- Flexible operation: The operation of the induction furnace is relatively flexible and can be adapted to different scales and types of scrap metal processing.

- Scrap metal purification and separation:

- Removal of impurities: Through the high-temperature heating and melting of induction electric furnaces, impurities in scrap metal can be effectively removed and the purity of the metal can be improved.

- Separating alloys: For alloys in scrap metal, induction furnaces can separate them so that metals with different components can be recycled independently.

- Energy efficiency:

- Efficient energy utilization: Compared with traditional combustion furnaces and other methods, induction electric furnaces can use electric energy more efficiently, reduce energy waste, and reduce energy costs.

- Environmental protection:

- Reduced gas emissions: Compared with traditional combustion methods, the operation of induction electric furnaces generally produces less gas emissions, helping to reduce environmental pollution.

- Low waste generation: Relatively little waste is generated during the operation of the induction furnace, which meets environmental requirements.

Technology Development and Future Trends

- Intelligence and automation:

- Application of sensing technology: Use sensor technology to monitor the quality and composition of scrap metal to achieve real-time data collection.

- Automated process: Introduce automation systems and machine learning algorithms to improve the efficiency of the production line, reduce human operating errors, and reduce waste of energy and resources.

- High-efficiency scrap metal separation technology:

- New separation methods: Develop more advanced and efficient separation technologies, especially for the separation of complex alloys and mixed metals.

- Innovation in physical and chemical methods: Use advanced physical and chemical methods, such as electric field separation, spectral analysis, etc., to improve the separation accuracy of scrap metal.

- Sustainable energy applications:

- Integration of Renewable Energy: Explore the integration of renewable energy into the scrap metal recycling process to reduce carbon footprint and reliance on non-renewable energy sources.

- Energy efficiency improvement: Improve energy efficiency and reduce environmental impact by improving induction furnaces and other heat treatment equipment.

- Advanced analysis and data processing:

- Big data application: Use big data analysis technology to comprehensively monitor the recycling system, optimize the production process, reduce energy waste, and improve scrap metal recycling efficiency.

- Artificial intelligence support: Use artificial intelligence technology to analyze scrap metal market trends, optimize supply chain management, and improve the commercial feasibility of scrap metal recycling.

- Development of circular economy:

- Product design innovation: Promote the development of a circular economy by designing products that are easier to recycle and reuse.

- Material traceability system: Establish a material traceability system to track the source, quality and processing of scrap metal, and improve the transparency of production and consumption.

- Green and environmentally friendly technologies:

- Green production: Promote the greening of the scrap metal recycling industry and use environmentally friendly technologies to reduce the generation of waste and pollutants.

- Wastewater treatment technology: Research and apply more effective wastewater treatment technology to reduce the environmental burden in the production process.

- International cooperation and standard setting:

- International cooperation: Strengthen international cooperation, share advanced technologies and best practices, and promote the sustainable development of the global scrap metal recycling industry.

- Standard setting: Develop more stringent scrap metal recycling and processing standards to ensure a high-quality and efficient recycling process and improve the market competitiveness of scrap metal.