When considering the use of an induction furnace for steel melting, there are several important factors and aspects to be aware of. We’ve compiled ten key points for you to learn.

1. Technical Specifications

- Power Supply: Understand the power requirements, which can range from a few kilowatts for small furnaces to several megawatts for industrial-scale operations. Ensure that the electrical infrastructure can support the furnace’s power needs.

- Frequency: Induction furnaces operate at different frequencies (low, medium, high). The choice of frequency affects the heating efficiency and depth of penetration into the metal.

- Capacity: Induction furnaces come in various sizes, with capacities ranging from a few kilograms to several tons. Choose a furnace that matches your production scale.

2. Design and Components

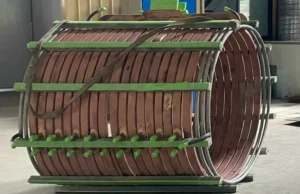

- Induction Coil: The coil design, material (usually copper), and cooling method are critical for efficient operation. The coil generates the magnetic field that heats the metal.

- Crucible: The container where the metal is melted. Crucibles must be made of refractory materials that can withstand high temperatures and are resistant to thermal shock.

- Lining: The furnace lining (refractory material) must be durable and periodically replaced to maintain efficiency and safety.

3. Operational Parameters

- Melting Temperature: Steel melts at around 1,370 to 1,540 degrees Celsius (2,500 to 2,800 degrees Fahrenheit). The furnace must be capable of reaching and maintaining these temperatures.

- Melting Time: Influenced by the furnace’s power and the size of the charge. Efficient melting cycles optimize productivity.

- Cooling System: Essential to prevent overheating of the coil and other components. Typically involves water-cooled systems.

4. Material Handling

- Charge Material: Quality and composition of the scrap or raw material significantly affect melting efficiency and steel quality. Proper segregation and preparation of the charge material are essential.

- Alloy Additions: Adding alloying elements (like chromium, nickel, etc.) must be precisely controlled to achieve the desired steel grade.

5. Process Control

- Temperature Monitoring: Accurate temperature control is crucial for producing high-quality steel. Use pyrometers or thermocouples for precise monitoring.

- Atmosphere Control: Some applications may require controlled atmospheres (inert gases) to prevent oxidation or contamination.

6. Efficiency and Energy Consumption

- Energy Efficiency: Induction furnaces are generally energy-efficient, but the actual consumption depends on operational practices and furnace design.

- Thermal Efficiency: Insulation and refractory quality impact thermal efficiency. Regular maintenance of the lining can improve performance.

7. Maintenance and Safety

- Maintenance: Regular inspection and maintenance of the coil, refractory lining, and cooling systems are crucial to prevent downtime and extend furnace life.

- Safety Measures: Implement robust safety protocols, including protection against electrical hazards, high temperatures, and handling of molten metal.

8. Environmental Considerations

- Emissions: Induction furnaces have lower emissions compared to fossil fuel-based furnaces. However, controlling fugitive emissions and ensuring proper ventilation is necessary.

- Waste Management: Proper disposal of refractory waste and managing slag generated during melting is important for environmental compliance.

9. Economic Factors

- Initial Investment: Induction furnaces can be expensive to install. Evaluate the return on investment based on energy savings, productivity, and quality improvements.

- Operating Costs: Consider costs associated with electricity, maintenance, refractory materials, and labor.

10. Regulatory Compliance

- Standards and Certifications: Ensure that the furnace and its operation comply with industry standards and local regulations regarding safety, emissions, and quality.

- Training: Operators should be well-trained in using and maintaining the furnace, understanding safety protocols, and handling molten metal.

Conclusion

Induction furnaces offer numerous advantages for steel melting, including efficiency, flexibility, and reduced environmental impact. However, successful operation requires careful consideration of technical specifications, operational parameters, material handling, process control, and maintenance. By understanding these factors, operators can maximize the benefits of induction furnaces and produce high-quality.

ShenGuang provides equipment for the production of stainless steel and alloy steel for the foundry industry.