Rincian produk

Induction smelters are devices that use medium-frequency electric currents to heat and melt metals and other high-temperature materials. They are widely used in various industries, such as metallurgy, mining, perhiasan, and aerospace, for producing alloys, castings, ingots, and other products. Induction smelters have many advantages over traditional furnaces, such as high efficiency, precise temperature control, low pollution, and easy operation.

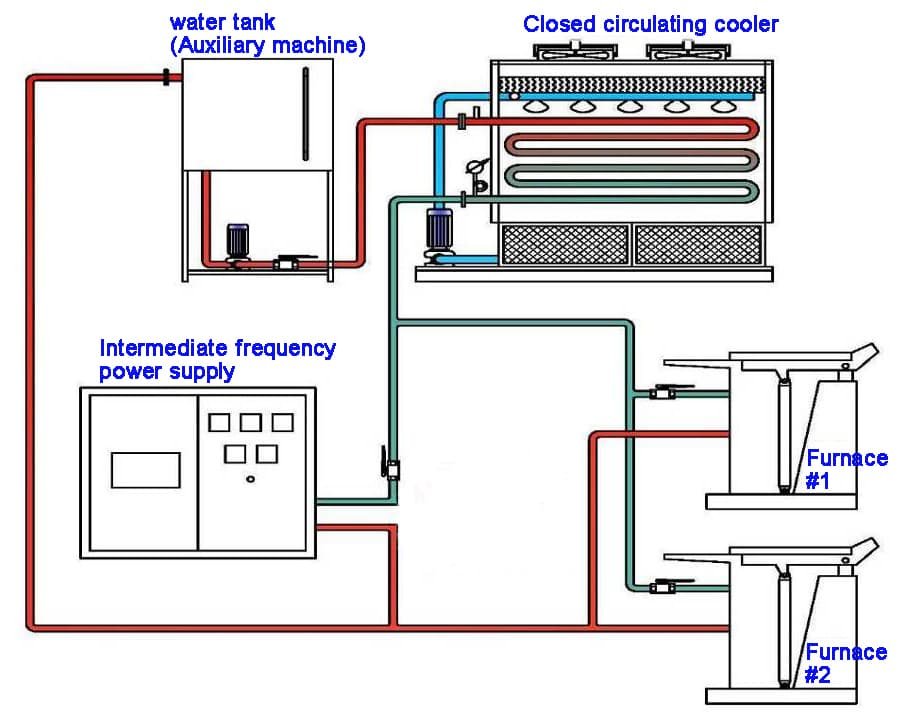

Induction smelters work by creating a magnetic field around a coil that contains the material to be melted. The magnetic field induces eddy currents in the material, which generate heat and cause the material to melt. The temperature and power of the induction smelter can be adjusted by changing the frequency and voltage of the electric current. The melting process can be carried out in air, vacuum, or inert gas, depending on the material and the desired quality.

Induction smelters can melt a variety of metals and high-temperature materials, seperti baja, tembaga, aluminium, emas, perak, platinum, titanium, zirconium, and silicon. Some of these materials have special properties, such as high strength, tahan korosi, or magnetic behavior, that make them suitable for specific applications. Misalnya, platinum is used for making jewelry and catalytic converters, titanium is used for making aircraft and medical implants, and silicon is used for making solar cells and semiconductors.

Parameter Produk

| Kapasitas yang ternilai | 0.05T – 30T |

| Rentang Daya Terukur | 30KW – 12000KW |

| Rentang frekuensi | 250Hz – 2500Hz |

| Rentang Tegangan Sebaris | 380V – 1500V |