Metal smelting has always been one of the cornerstones of human civilization. With the continuous advancement of science and technology, the field of metal smelting has also experienced major revolutionary changes. Among them, induction melting technology is undoubtedly an outstanding achievement in the field of metal smelting. We will delve into the principles, application areas and future prospects of induction metal melting to demonstrate the pinnacle of this modern furnace technology.

Part 1: Principles of Induction Melting of Metals

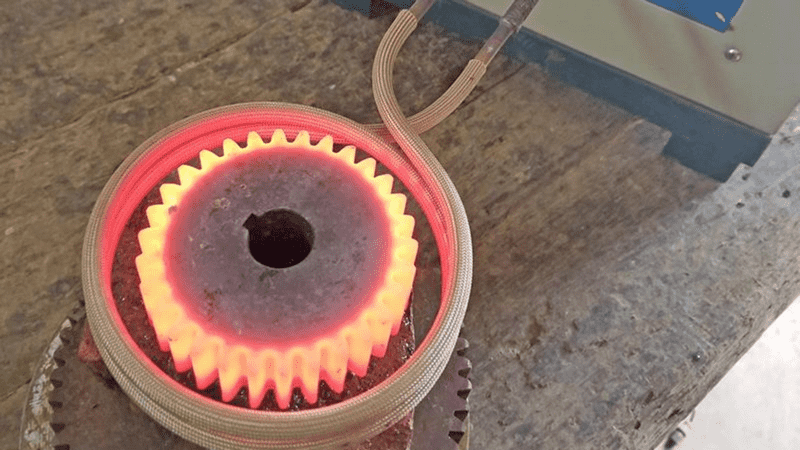

Induction metal melting is a metal smelting method based on the principle of electromagnetic induction. The basic principle is to pass high-frequency current through a coil into a conductive material (usually metal) to generate an induced current inside the conductive material. These induced currents form a closed loop within the conductive material, generating heat to heat the metal to its melting point. The main principles of induction melting can be summarized into the following key steps:

- High-frequency, medium-frequency, and low-frequency currents pass into the coil: high-frequency current is generated through the power supply and passed into the induction coil.

- Electromagnetic induction: The current generates a strong electromagnetic field in the induction coil, causing the free electrons in the conductive material to start moving.

- Movement of free electrons: Free electrons continuously move in the electromagnetic field, generating induced current. These induced currents generate heat inside the conductive material.

- Heating the material: The thermal effect of the induced current heats the metal to the melting point, thereby realizing the melting of the metal.

One of the key advantages of induction melting technology is its non-contact nature, allowing it to handle metal smelting in high-temperature, corrosive, or hazardous gas environments. Bukod pa rito, it has excellent energy efficiency because energy is mainly used to heat the required metal, with almost no energy wasted.

Part 2: Application fields of induction metal melting

Induction melting technology is widely used in many fields, including but not limited to the following aspects:

- Metal smelting: Induction smelting is widely used for the extraction and refining of gold, silver, copper, aluminyo, and other non-ferrous metals. Its high temperature and high efficiency make it a key tool in the modern smelting industry.

- Metal casting: Induction melting can be used to manufacture high-quality, complex-shaped castings, such as engine parts, aircraft parts, automobile parts, atbp. It provides more precise temperature control and reduces the formation of pores and impurities.

- Electronic waste recycling: Induction smelting can be effectively used to recycle precious metals, such as gold, silver, platinum, etc., from discarded electronic equipment, helping to reduce the impact of electronic waste on the environment.

- Environmentally friendly applications: Induction melting technology can be used to process hazardous waste and scrap metal, melting them into reusable materials, helping to reduce waste emissions and resource waste.

Part 3: Future Development Prospects

Induction metal melting technology constantly evolves and improves to adapt to changing needs and challenges. Future development prospects include the following aspects:

- Material innovation: With the emergence of new materials, induction melting technology will continue to adapt to the needs of new materials, including high-temperature superconducting materials, advanced alloys, atbp.

- Automation and intelligence: Automation systems and intelligent control will further improve the production efficiency and quality control of induction melting.

- Environmental sustainability: Green smelting technology will become a focus in the future to reduce energy consumption and environmental pollution.

- Cross-industry applications: Induction melting technology will be expanded to more fields, such as aerospace, energy storage, medical devices, etc., to meet the growing market demand.

Conclusion

Induction metal melting is an outstanding technology in the field of metal smelting, which achieves efficient and high-quality metal smelting through the principle of electromagnetic induction. It plays a key role in multiple application fields and has broad future development prospects. Through continuous innovation and improvement, induction melting technology will continue to bring new breakthroughs and progress to the field of metal smelting, promoting the development and prosperity of modern industry.