The history and importance of copper

Copper, as an ancient and precious metal, was discovered and utilized by humans thousands of years ago. Its use in the Bronze Age, such as bronze vessels, weapons, etc., marked the development of civilization. Today, copper is widely used in electronics, construction, transportation and other fields, and has become one of the indispensable basic materials in modern society.

Basic process of copper melting

- Ore collection: Copper ore collection is the first step in copper smelting. Ore usually contains impurities such as sulfides, which require preliminary treatment through mineral processing equipment.

- Leaching and flotation: Through leaching and flotation, impurities in copper ores can be separated to obtain ores containing higher purity copper.

- Melting: The pre-processed ore is fed into the furnace, where the copper is melted through high temperatures and separated from other substances. This is the core process of copper smelting.

- Electrolysis: Electrolysis of molten copper to improve the purity of copper. Electrolysis is an efficient separation method that ensures a high standard of quality in the final product.

Technical innovation in copper melting

With the advancement of science and technology, copper smelting technology is also constantly innovating. New stove designs, efficient separation methods, green and environmentally friendly production processes, etc. are gradually promoting the development of the copper smelting industry. These innovations not only improve production efficiency, but also reduce the impact on the environment, in line with the concept of sustainable development.

Copper melting’s role in sustainable development

As an important industrial process, copper smelting must continue to evolve within the framework of sustainable development. Adopting clean production technologies, recycling waste materials, reducing energy consumption and other measures are key steps for copper smelting companies to develop towards sustainability. Only by ensuring efficient production can we better protect environmental resources and create better living conditions for the future.

The future of copper melting

Looking to the future, the copper smelting industry will face more challenges and opportunities. The development of emerging industries such as electric vehicles and renewable energy will further drive demand for copper. Therefore, copper smelting companies need to continue to innovate and improve production capabilities to meet market demand while maintaining environmental protection and sustainability.

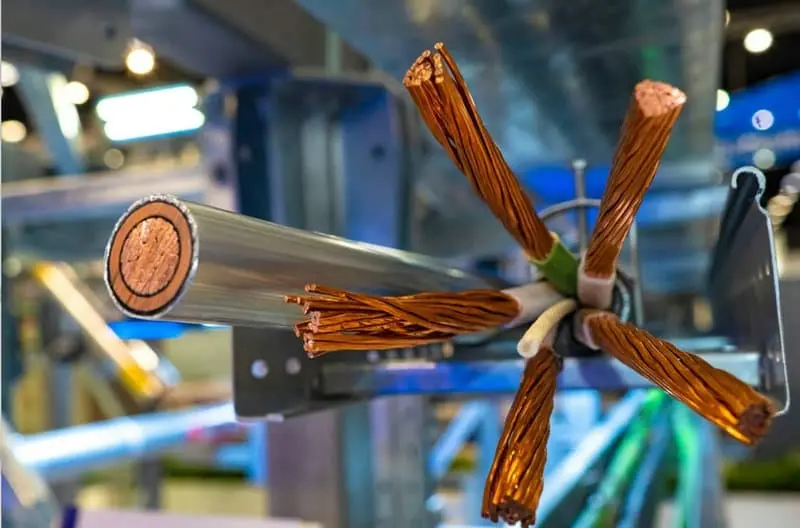

- Power and electronic industry support: Copper is an excellent conductive material and is widely used in the power and electronic industry. Cables, electronic components, transformers, etc. are all inseparable from the application of copper. In national development, the power and electronics industry is an important part of supporting infrastructure and high-tech industries, and the smelting of copper provides key materials for these industries.

- Development in the construction and transportation fields: Copper has excellent thermal conductivity and corrosion resistance and is widely used in the construction and transportation fields. For example, copper pipes are used in water supply and heating systems, and copper alloys are used to make ship and aircraft parts. In national development, construction and transportation are key areas related to urbanization and infrastructure construction, and copper smelting provides important support for these areas.

- The rise of emerging industries: With the rise of emerging industries such as electric vehicles and renewable energy, the demand for copper continues to increase. As an important component of electric vehicle batteries, solar cells, etc., copper plays an irreplaceable role in promoting the development of clean energy and green transportation. In terms of the country’s development of emerging industries, copper smelting has become a key factor in supporting industrial upgrading and sustainable development.

- Employment and economic growth: The copper smelting industry involves mining, smelting, manufacturing and other links, creating a large number of employment opportunities for the country. At the same time, the development of this industrial chain has also driven the prosperity of related industries and contributed significantly to the country’s economic growth. The healthy development of copper smelting is crucial to maintaining employment and promoting long-term stable economic growth.

- Technological innovation and international competitiveness: The technical level of the copper smelting industry is directly related to the country’s competitiveness in the international market. Through continuous technological innovation, improving production efficiency and reducing production costs, the country can achieve a more competitive position in the global copper market and promote the improvement of the country’s overall scientific and technological level.

Copper melting equipment

- Furnace: The furnace is one of the core equipment in copper smelting. Furnaces are used to heat copper ore or copper-containing materials to high temperatures to melt the copper and separate out other impurities. Furnaces are usually designed with high temperature and corrosion resistance in mind to ensure a stable and efficient smelting process.

- Leaching equipment: used for leaching and flotation of ores to separate valuable ores. These equipment include leaching pools, flotation tanks, etc., which achieve preliminary treatment of copper ore through chemical reactions and physical flotation.

- Electrolytic cell: The electrolytic cell is the key equipment to improve the purity of copper. Through electrolysis, molten copper is electrolytically decomposed and copper ions are deposited on the anode, thereby improving the purity of the product. Electrolyzers usually use special electrodes and electrolytes to ensure an efficient electrolysis process.

- Cooling equipment: A large amount of heat is generated during the smelting process, so cooling equipment is needed to prevent the equipment from overheating. Cooling equipment can include cooling water circulation systems, coolers, etc. to ensure that the equipment is within the appropriate operating temperature range.

- Dust removal equipment: The smelting process may be accompanied by the generation of smoke, dust and gas. In order to protect the environment and the health of workers, dust removal equipment needs to be used to collect and process dust.

- Automated control system: Copper smelting equipment is usually equipped with advanced automated control systems to monitor and regulate the entire smelting process. This includes real-time monitoring of temperature, pressure, flow and other parameters to ensure the stability and controllability of production.

- Waste gas treatment equipment: In order to meet environmental protection standards, copper smelting equipment usually also includes waste gas treatment equipment to treat the waste gas generated during the smelting process and reduce the negative impact on the environment.

Summarize

Copper melting is an area full of challenges but also opportunities. By gaining a deeper understanding of copper’s properties, smelting processes and technological innovations, we can better prepare for future changes and drive the copper smelting industry in a more sustainable and prosperous direction.

——First release date: January 22, 2024