How to Melt Aluminum

Melting aluminum requires careful handling and proper equipment due to its high melting point and

Melting aluminum requires careful handling and proper equipment due to its high melting point and

Melting zinc in an induction furnace is a process used in various industries for applications

The various processes in the use of the medium frequency furnace are also very important

We are excited to announce that Ningbo Shenguang Electric Furnace Co., Ltd. will be participating

Things you need to know about induction furnace for copper melting. 1. How Induction Furnaces

When considering the use of an induction furnace for steel melting, there are several important

The history and importance of copper Copper, as an ancient and precious metal, was discovered

KGPS Technology Working principle Control circuit principle The entire control circuit, except for the inverter’s

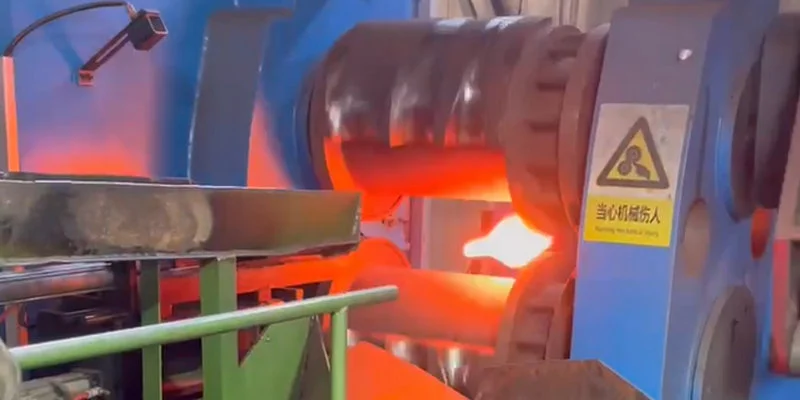

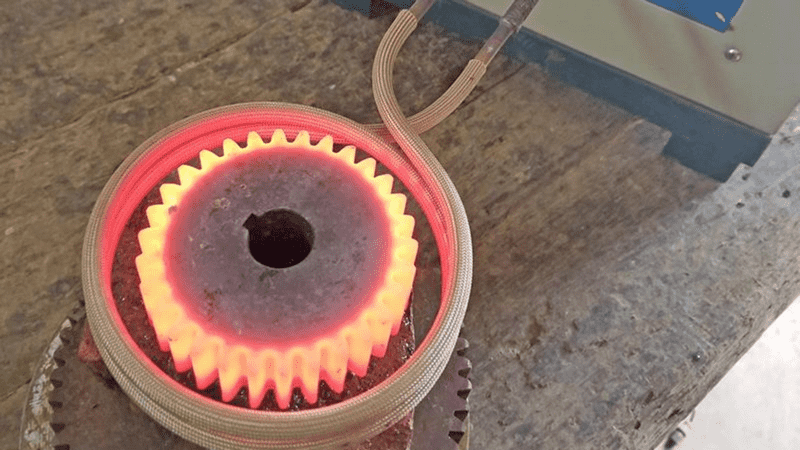

Heat treatment is a crucial process in materials science, primarily used to alter the physical

What is induction melting equipment? Induction melting equipment is a type of technology used to

Melting gold is a process that requires specific equipment and safety measures due to the

Understanding Silver’s Properties Safety Precautions Equipment Needed Melting Process Cooling and Handling Post-Melting Processing Additional

Induction furnaces and electric arc furnaces are both used for melting metals, but they operate

Choosing the right induction furnace manufacturer is crucial for ensuring that your investment meets your

Four methods of heating metal with electrical energy Resistance heating Resistance heating is a method

Melting and smelting are processes that involve the transformation of substances from one state to

The Current transformer is an instrument that works based on the principle of electromagnetic induction.

Copper plays a dual role in steel production, serving both as a beneficial alloying element

The full name of IGBT is Insulated Gate Bipolar Transistor.It is a composite fully controlled

Chromium is the most widely used and most commonly used alloy element. Chromium has a

According to the main matrix elements of the alloy, high-temperature alloys can be mainly divided

What is bottom slag? Bottom slag refers to the slag that is deliberately placed at

Crucible materials for induction furnace smelting should meet the following requirements. 1. The crucible material

Nickel and cobalt are elements with similar physical and chemical properties. They are alloy elements

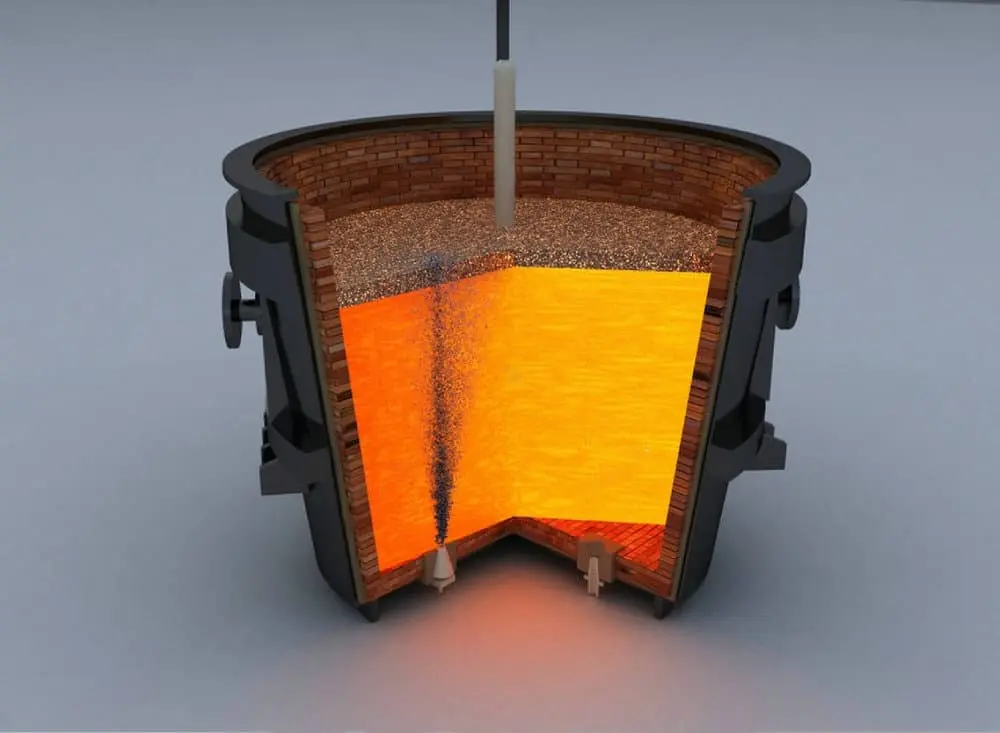

Induction melting furnaces are mainly divided into two types: cored and coreless. Among them, coreless

Induction furnaces are heating devices widely used in industrial production. Its working principle is based

Furnace Construction Tools Pre-furnace Preparation Work Before furnace construction, thorough preparation is essential. This includes:

Based on Power Frequency: 1. Medium frequency furnace The power frequency range of the medium

Working principle and heating method Medium frequency electric furnace: The induced current generated by electromagnetic

Deoxidation Effect of Carbon in Vacuum In a vacuum environment, carbon demonstrates remarkable deoxidation capability,

Melting nickel-based alloys in intermediate frequency furnaces demands meticulous attention to prevent common issues such

The metallic and non-metallic raw materials involved in induction furnace smelting are broadly classified into

How to take correct measures to improve the quality level of mold steel during medium

Thyristor intermediate frequency (IF) power supply is a crucial static frequency conversion device leveraging thyristor

The role of furnace lining in induction metal melting furnace The furnace lining in an

When a steel plant smelting aluminum, the choice between an electric induction melting furnace or

Use Industrial Pure Iron for Cleaning and Maintenance: Cleaning the induction crucible with industrial pure

Application of intermittent melting principle in intermediate frequency furnace At the beginning of smelting in

Discover effective methods for accurately measuring metal melting temperatures with this comprehensive guide. Learn the

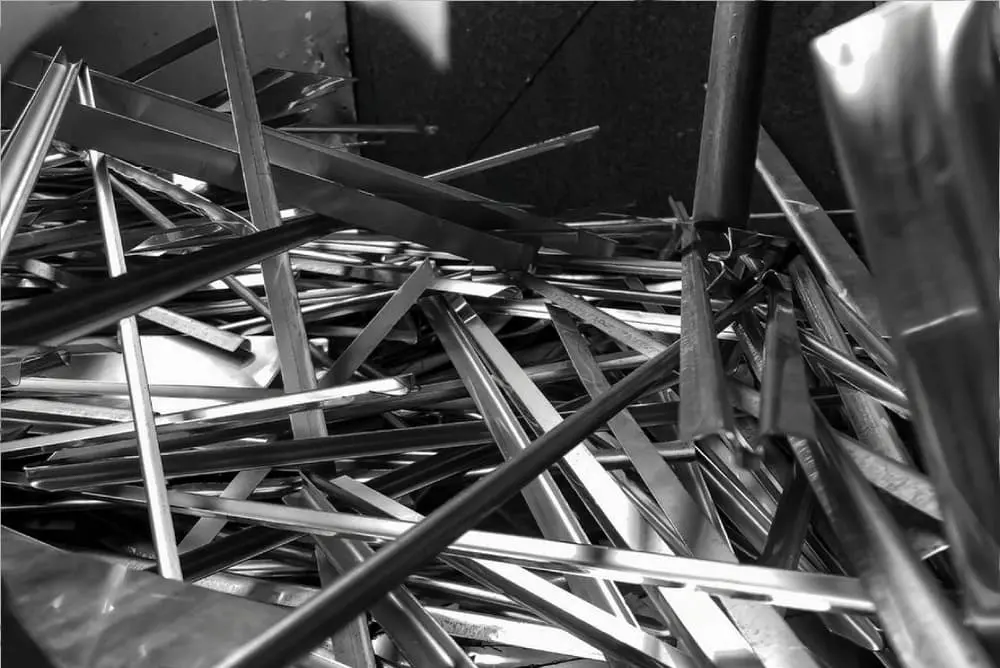

Importance of Scrap Metal Recycling: What are the sources of steel scrap from steel mills?

(1) Low gas content in smelted steel. The high viscosity and low permeability of the

Before loading materials into the medium-frequency induction furnace for melting, several checks and verifications must

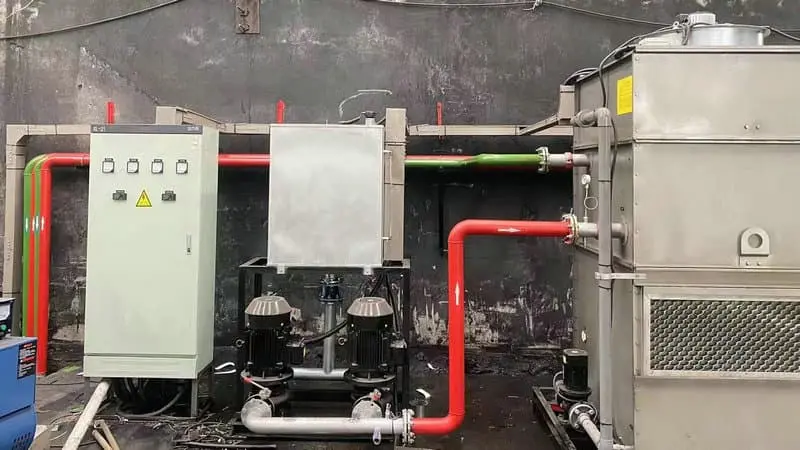

(1) Induction coil and capacitor cooling water system. Adopt industrial pressure water cooling. The cooling

Induction furnaces, as an advanced smelting technology, play a vital role in the global steel

Induction furnace is divided into core and coreless two kinds, the most common application is

Introduction: In the realm of metallurgical advancements, the emergence of pressurized induction furnace smelting has

Iron melting is a complex and sophisticated process involving a variety of processes and technologies.

Heating Preheating: Some materials require gradual heating to minimize thermal shock. This initial heating is

Regarding the induction furnace prices, you must know 20 attention points. 1. Technology and specifications:

Induction melting process The induction melting process is a modern metal processing method that uses

Annealing: Heating the metal above its critical temperature and holding it there for a period

the choice between gas and electricity for metal smelting depends on various factors, including cost,

SHEN GUANG Furnace will participate in MTM EXPO·SHANGHAI 2023 from 29th November to 1st December.

Energy efficiency Induction melting furnace offer significant advantages in terms of energy efficiency. Its energy

What is silver Silver is a chemical element, represented by the symbol Ag in the

Induction furnaces are a kind of thermal processing equipment. Its basic principle is to use

Coreless type induction furnace is an industrial equipment used for heating metals. It is mainly

An induction furnace crucible is a special industrial device used for induction heating, often used

Metal smelting has always been one of the cornerstones of human civilization. With the continuous

Aluminum melting is the process of extracting and processing from ore or scrap into usable

We are here for your questions anytime 24/7, welcome your consultation.

Copyright © 2025 ShenGuang. All rights reserved.